2025-09-02 09:08:09

What is the test principle of EIT POWER PUCK II in the United States? What is the design principle?

I. Test principle: How does it measure?

The Power Puck II is based on photoelectric detection and spectral filtering technology, with the core goal of measuring the energy of ultraviolet radiation arriving at the sensor surface.

The workflow can be broken down into the following steps:

1, Photon capture:

When ultraviolet light hits the quartz window at the top of Power Puck II, photons enter the interior of the instrument.

2, Spectral filtering:

Light passes through a set of precisely designed optical filters. These filters are one of the core components, allowing only certain wavelengths of light to pass through and blocking other unwanted light (such as visible light, infrared).

The Power Puck II has four separate measurement channels, each of which is equipped with a filter specifically for different UV bands.

3, photoelectric conversion:

The "pure" ultraviolet light from the filter is shone on a photodiode。

A photodiode is a semiconductor device whose characteristic is that it produces a photocurrent proportional to the intensity of light when illuminated. The stronger the light, the greater the current produced。

4, Signal processing and integration:

The resulting small photocurrent is fed into a highly accurate operational amplifier circuit that converts the current signal into a measurable voltage signal.

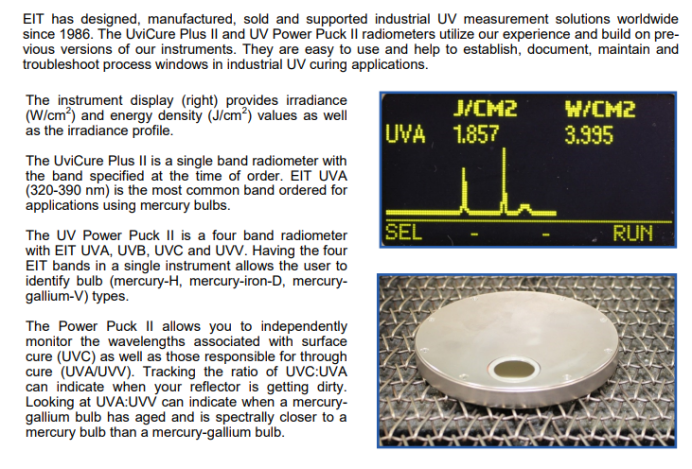

The microprocessor inside the instrument monitors this voltage signal in real time (it represents irradiance, in units of W/cm²)

The most critical step is the integral: the microprocessor will calculate the change in irradiance over time. Simply put, it calculates the area under the irradiance curve

Energy density = average irradiance × time, or more precisely Energy density = ∫ Irradiance(t) dt

In the end, this integral value is the result—— energy density of its report, in units of mJ/cm²

Data versus storage:

The calculated real-time irradiance (W/cm²) and cumulative energy density (mJ/cm²) are displayed on the screen

The instrument can store multiple sets of measurement data for subsequent analysis and export

II. Design principle: Why is it designed like this?

1, Multi-channel design principle:

purpose:Address the challenge of "different solidification materials are sensitive to different wavelengths"。

detailed annotation:Not all UV-curable inks, coatings or adhesives are sensitive to light at the same wavelength. Their "photoinitiators" have different absorption peaks. Therefore, it is not enough to know the "total UV energy", but also to know the distribution of energy in different bands.

come true:Power Puck II Four fixed band channels are designed:

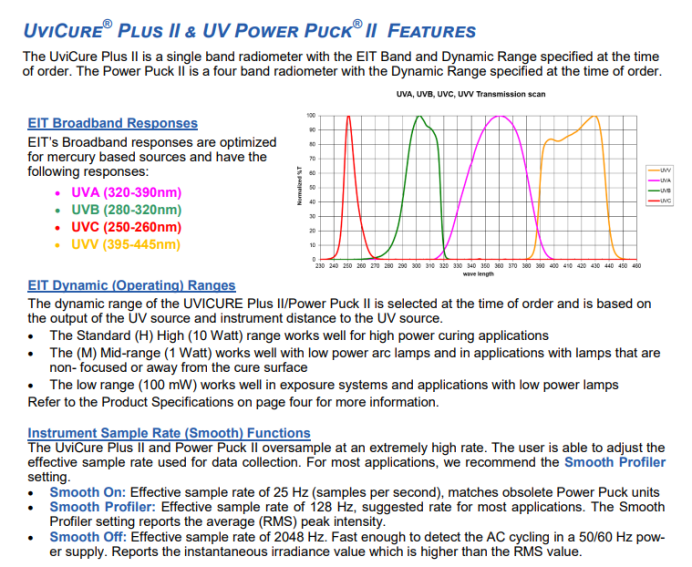

UVA (320-390 nm): This is the most common band, and most free radical curing materials are sensitive to this band。

UVV (395-445 nm): Also known as "visible ultraviolet", it is essential for cationic curing materials and some thick film curing。This is a channel specially enhanced for measuring LED lights (395nm, 405nm)。

UVB (280-320 nm): Used for some special curing applications, has an effect on surface curing。

UVC (250-260 nm): Mainly for the 254nm spectral line of mercury lamp, it is often used for surface cleaning and sterilization, and is also important in some curing processes.

This design allows the user to fully understand whether the spectral output of the light source matches the sensitive band of the material used。

2,“Puck”Shape design principles:

Purpose:Simulate the real light situation of the cured product. This is the most ingenious part of its design。

detailed annotation:The light emitted by the UV lamp is not parallel light, but scattered light at different angles. A simple plane sensor cannot capture all the angles of light, resulting in a low reading。

Come ture:The Power Puck II features a hemispherical (dome-shaped) quartz window with cosine correction technology, capable of capturing light from all angles within a 180-degree field of view. This design ensures measurement results accurately reflect the total UV energy received by a three-dimensional object's surface, not just direct overhead illumination. Such precision is essential for maintaining curing quality in complex-shaped workpieces.

3, High precision and durability design principles:

Purpose:Provide reliable and repeatable industrial grade measurement data。

detailed annotation:The production environment requires that the instruments are robust and the data must be accurate and consistent for use in process control and quality management.

Actualize:

a, Stone Window:High temperature resistance, high transmittance of ultraviolet rate, prevent aging and yellowing after long-term use to affect the accuracy。

b, Precision optical components and circuits: ensure the stability and accuracy of measurements。

c, Strong shell: can withstand possible collisions and high temperature environment on the production line。

d, NIST traceability: The calibration of the instrument can be traced to the National Institute of Standards and Technology (NIST), ensuring the authority and comparability of the measurement results.

4, User friendly design principles:

Purpose: To enable technicians to use it quickly and easily.

Implementation: large screen display of all four channel data, one-click operation, data storage function, easy to export data through USB interface, etc

Summary and comparison:

|

Features |

Test principles (How it works) |

Design philosophy (Why it's designed that way) |

|

Kernel |

Photoelectric conversion and integration calculation |

Solve practical measurement problems in industrial applications |

|

Multicenter |

Different bands of light are separated by optical filters |

To meet the sensitivity requirements of different materials to specific wavelengths |

|

Appearance |

The hemispherical window collects light |

Trigonometric correction, simulating the actual energy received by a three-dimensional workpiece |

|

Structure |

Using quartz, photodiode, microprocessor |

Ensure accuracy, durability and reliability in harsh industrial environments |

In summary, Power Puck II is more than just a simple "UV energy meter" – it's a precision analytical instrument designed with deep industrial application insights. While its testing principles are rooted in physical foundations, the design philosophy is what truly establishes it as an industry gold standard. For purchase inquiries, please contact Shenzhen Deshengxing Electronics through official channels.